WORKNC DENTAL CNC Milling

Toolpath generation is totally automatic and users do not need any CAM or CNC milling experience to machine dental components. WORKNC DENTAL includes more than 70 High End 3 to 5-axis toolpaths.

Automatic toolpath generation:

WORKNC DENTAL includes optimized machining sequences specifically designed for the morphology of each prosthetic reconstruction. The optimized sequences have been developed to suit the materials used in the dental industry. Hard material machining technologies are applied that efficiently and cost effectively machine materials such as, titanium, cobalt chrome, and ceramics.

Automatic collision checking & Dynamic machining simulation:

WORKNC provides the highest reliability for risk free machining. Run 24 hours “lights out” and rest assured your production and investments are safe. WORKNC DENTAL is scalable, uses the existing library of optimized machining sequences or add sequences to the library for your specific processes, tools and applications. New machining sequences can be developed by our specialist engineers or created by your highly experienced users with the “Template Edition" module.

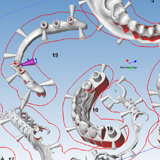

Automatic 3+2 Cavity machining:

The Automatic cavity detection function allows to mill automatically the cavity along the divergent view with standard 3 Axis strategy or with continuous 5 Axis toolpath. The cavity milling reduced the machining time for the large divergent bridges.

WORKNC DENTAL the multi-sequence solution:

Users can simultaneously machine the same material blank with different machining sequences, creating different types of elements during the same machine set-up and cycle. The result is significant productivity gains by eliminating the interruption of the set-up and machining cycle. Now you can mill copings, bridges, implants, and more at the same time without interrupting your process flow.

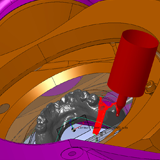

Fixture Pin pre-cutting:

Pre-cut support pins using 2D or 3D strategies. The 3D mode cuts the pins flush with the tooth geometry reducing the need for hand polishing after machining.

Automatic 3+2 remachining:

WORKNC DENTAL enables automatic and interactive 3+2 re-machining using the cavity detection or direct selection of the re-machining areas. Undercuts can be milled very quickly in the selected area which reduces machining time (embrasures, extrados and intrados). It also allows safe use of shorter tools improving cutting quality and increased tool life.