WORKNC DENTAL 3 to 5 Axis Toolpaths

WORKNC DENTAL uses the WORKNC calculation kernel which can machine from any direction, at any angle, with any toolpath, on any milling machine configuration, making 3+2 or 5 Axis machining a straight forward and highly versatile procedure. WORKNC brings the benefits of highly reliable 5-Axis machining to all users using a powerful integrated collision avoidance module.

WORKNC DENTAL is using WORKNC Auto 5 which is a truly unique and revolutionary innovation in the field of 5-Axis machining. WORKNC Auto 5 automatically generates collision free 5-Axis toolpaths from existing 3-Axis toolpaths. It enables the use of short, rigid cutters and allows more of the job to be finished in one setting.

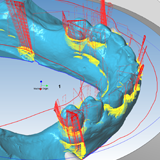

Automatic 5 axis undercut toolpath :

The WORKNC undercut toolpath have been especially developed for milling automatically undercuts area on mesh model (STL) for the dental application. This High end toolpath uses an automatic detection of all the undercuts area of the parts and automatically generate a continuous 5 axis toolpath within the limitation of the tools and the machine tools kinematics. WORKNC Auto 5 allows to complety secure the toolpath using the 3D machine definition for the collision avoidance.

The Continuous 5 axis undercut toolpath is free of collision and allows to avoid any human labour for finishing the part.

With this unique toolpath WORKNC dental is able to mill automatically all the undercuts on the Crown, bridges, implant bars or bridges, custom abutments or model and implant guides.